Aturan Cut LQ-TOOL

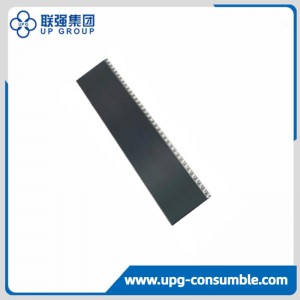

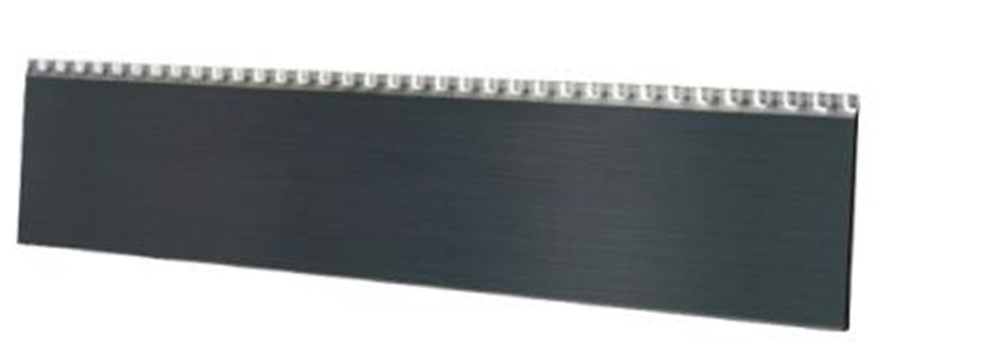

Aturan Cutting Mirror (CBM)

● Mirror pinggiran piso cetha

● Rong jinis: <52°,<42°,<30°

● Cocog kanggo nglereni kertas jumlahe kurang saka 400000pcs

● Bisa bend kanggo sembarang wangun geometris.

● Bahan: DE

● pinggiran:CB LCB

| kekandelan | 0,53 mm (1,5 PT) | 0,71 mm (2 PT) |

| dhuwur | 23,6 mm | 23,8 mm |

| Spesifikasi Ketebalan | Nomer | Warna badan | Sudut pinggir | Cathetan |

| 0.71*23.6/23.8 | CBM-78 | Ireng/Putih | 30 derajat | Kekerasan Edge HRC55-56° Kekerasan awak HRC 35-36° |

| 0.71*23.6/23.8 | CBM-88 | Ireng/Putih | 42/45 derajat | Kekerasan Edge HRC57-58° Kekerasan awak HRC 37-38° |

| 0.71*23.6/23.8 | CBM-98 | Ireng/Putih | 52 derajat | Kekerasan Edge HRC58-59° Kekerasan awak HRC 40-41° |

Aturan Cutting Grinding

● Abrasive maching pinggiran piso cetha

● Loro jinis: <52°, <42°, <30°

● Cocog kanggo nglereni kertas jumlahe kurang saka 200000pcs

● Bisa bend kanggo sembarang wangun geometris

Bahan: KR, DE

Edge: A.CB, B.LCB

| kekandelan | 0,71 mm (2 PT) |

| dhuwur | 22,8-30 mm |

| Spesifikasi Ketebalan | Nomer | Warna badan | Cathetan |

| 0,71 mm | GL-70 | Badan Emas | Kekerasan Inti Hrc36-37(Alus) |

| GL-80 | Kekerasan Inti 38-39(Sedang) | ||

| GLD-70 | Bahan Jerman (Alus) | ||

| GLD-80 | Bahan Jerman (Medium) |

Aturan Pemotongan Gillet (GE)

Pinggiran polesan lan landhep, ndadekake kemampuan mekanik-ganti radikal.

Digunakake kanggo wangun-Cutting saka label adesif, PVC lan barang tamparan-UP liyane

Bahan: CN, DE

Edge: A.CB, B.LCB

| kekandelan | 0,53 mm (1,5 PT) | 0,71 mm (2 PT) |

| dhuwur | 23,6 mm | 23,8 mm |

| Spesifikasi Ketebalan | Nomer | Warna badan | Cathetan |

| 0,71 mm | GE-70 | Awak biru-ireng | Kekerasan Inti Hrc36-37(Alus) |

| GE-80 | Awak biru-ireng | Kekerasan Inti 38-39(Sedang) | |

| GED-80 | Awak biru-ireng | Bahan Jerman | |

| 1,07 mm | GRB-70 | Awak biru-ireng | Kekerasan Inti Hrc36-37(Alus) |

| GRB-80 | Awak biru-ireng | Kekerasan Inti 38-39(Sedang) | |

| GRB-90 | Awak biru-ireng | Kekerasan Inti 40-41(Keras) |

Aturan label piso self-adhesive (HL)

Digunakake kanggo mbentuk kabeh jinis label adesif

Bisa ditekuk ing wangun geometris apa wae

Bahan: CN JP GM

Pinggir: A: Pisau pisau tunggal CB, B: LCB bilah ganda

| kekandelan | 0,45 mm (1,27 PT) |

| dhuwur | 7.0-12.0mm |

| Spesifikasi Ketebalan | Nomer | Warna badan | Cathetan |

| 0,45 mm | HL-50 | Pinggir Putih | Kekerasan inti HRC41-43 |

| HL-60 | Black Edge | Kekerasan inti HRC39-40 | |

| HL-70 | Badan Putih | Kekerasan inti HRC39-40 | |

| HL-80 | Badan Emas | Kekerasan inti HRC39-40 |

Aturan Pemotongan Khusus (KL)

Digunakake kanggo spacer, plastik, serat lan liya-liyane, potongan potong bisa ngluwihi 800000pcs

Bisa ditekuk ing wangun geometris apa wae.

Bahan: CN JP GM

Pinggir: A: Pisau pisau tunggal CB, B: LCB bilah ganda

| Spesifikasi Ketebalan | Nomer | Warna badan | Cathetan |

| 0,71 mm | KL-70 | Awak biru-ireng | Kekerasan Inti HRC 36-37°(Alus) |

Cutting Kucing Ireng (BL)

Digunakake kanggo spacer, plastik, serat lan sapiturute, potongan potong bisa ngluwihi 800000pcs.

Bisa ditekuk ing wangun geometris apa wae.

Bahan: CN JP GM

Pinggir: A: Pisau pisau tunggal CB, B: LCB bilah ganda

| Spesifikasi Ketebalan | Nomer | Warna badan | Cathetan |

| 0,71 mm | BL-80 | Awak biru-ireng | Kekerasan Inti HRC 36-39°(Sedang) |

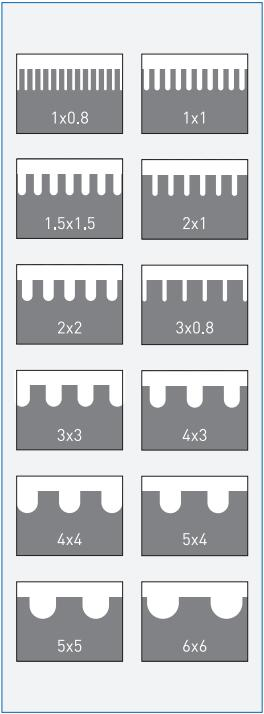

Aturan Perfpration (WL)

1. Gigi persegi 3 untu/1", 4 untu/1", 6 untu/1", 8 untu/1", {1:1}, 10 untu/1", 16 untu/1"

2. Digunakake kanggo mbentuk-motong tagihan

Bahan: □CN

Edge: Grinding

| kekandelan | 0,45 mm (1,27 PT) | 0,71 mm (2 PT) | ||

| dhuwur | 8 mm | 23,6 mm | 23,8 mm | |

| Ukuran | 1: 1; 2: 1; 3: 1; 6: 1; 8: 1; 10: 1; 12: 1; 16: 1 | |||

| Spesifikasi Ketebalan | Nomer | Warna badan | Cathetan |

| 0,71 mm | WL-90 | Awak biru-ireng | Kekerasan Inti HRC 40-41°(Keras) |

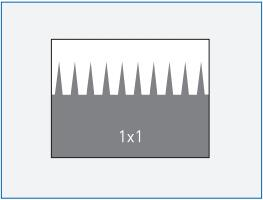

Aturan Gigi Tajam (WLS)

1. Cutter sekte pindho

2. Gigi tajam 16 untu/1''

3. Digunakake kanggo ngematake break mboko sithik Spesifikasi: 510 × 8.16 × 0.75mm (aturan Formulir Bisnis pinggiran siji), (2:1,3:1,1:1)

Bahan: CN, JP, GM

Edge: CB, LCB

| kekandelan | 0,71 mm(2 PT) |

| dhuwur | 23,0-23,8 mm |

| Ketebalan spesifikasi | Nomer | nerangake | Cathetan(atose)syarat |

| 0,71 mm | WLS-90 | Awak biru-ireng | Kekerasan Inti Hrc40~41(Hard) |

Pemotong Sisi (DEX)

1. Digunakake kanggo wangun-nglereni saka amba aright

Bahan: CN, JP, GM

Edge: CB, LCB

| kekandelan | 0,71 mm (2 PT) | 1,07 mm (3 PT) |

| dhuwur | 22,8-50,0 mm | |

| Ketebalan spesifikasi | Nomer | nerangake | Remark (kekerasan) syarat |

| 0,71 mm | DEX-90 | Awak biru-ireng | Kekerasan Inti Hrc40~41(Keras) |

Aturan Pemotongan Tinggi (DLX)

1 Digunakake kanggo wangun-nglereni saka karton lan ing

Bahan: CN, JP, GM

Edge: CB, LCB

| kekandelan | 0,71 mm (2 PT) | 1,07 mm (3 PT) |

| dhuwur | 30.0-50.0mm | |

| Spesifikasi Ketebalan | Nomer | nerangake | Cathetan |

| 0,71 mm | DLX-80 | Awak biru-ireng | Kekerasan Inti Hrc38~39(Medium) |

| 1,07 mm | DLE-80 |

Aturan Waved (BL)

1.Dhuwur impressing digawe miturut panyuwunan

2. Digunakake kanggo kothak lan karton A TYPE 10 PCS/B TYPE 8PCS/C TYPE 6PCS/D TYPE 4.5PCS/E TYPE 3PCS

Bahan: CN, JP, GM

EDGE: CB, LCB

| kekandelan | 0,71 mm (2 PT) |

| dhuwur | 23,6-23,8 mm |

| Spesifikasi Ketebalan | Nomer | nerangake | Cathetan |

| 0,71 mm | BL-70 | Awak biru-ireng | Kekerasan Inti Hrc 36~37 |

Aturan Creasing

1 Dhuwur impressing digawe miturut panjalukan sampeyan

2 Ketebalan: (2PT) 0,71mm, (3PT)1,07mm, (4PT)1,42mm, (6PT)2,10mm

Bahan: CN, JP, GM

Edge: CB, LCB

| kekandelan | 0,71 mm (2 PT) | 1,07 mm (2 PT) | 1,42 mm (2 PT) | 2,10 mm (2 PT) |

| dhuwur | 22,8 ~ 30,0 mm | |||

| Spesifikasi Ketebalan | Nomer | nerangake | Cathetan |

| 0,71 mm | EL-90 | Awak biru-ireng | Kekerasan Inti Hrc 41~43 |

| ELD-90 | Badan Putih | Kekerasan Inti Hrc43~45 | |

| EL-70 | Taiwan | Kekerasan Inti Hrc38~39 (Medium) | |

| EL-80 | Taiwan | Kekerasan Inti Hrc35~36 (Alus) | |

| 1,07 mm | ELD-70 | Awak biru-ireng | Kekerasan Inti Hrc37 |

| ELD-80 | Awak biru-ireng | Kekerasan Inti Hrc39 | |

| 1,42 mm | ELC-70 | Awak biru-ireng | Kekerasan Inti Hrc36 |

| 2,1 mm | ELB-70 | Awak biru-ireng | Kekerasan Inti Hrc35 |

| 0,71 mm | EV-90 | Awak biru-ireng | Kekerasan Inti Hrc41~43(Kerut Tipis Ndhuwur) |

Ringkesan unsur konstituen saka piso pemotong die

| Jinis Knife | Pisau Low-bladed/Pisau High-bladed kanthi rong tahap/ Pisau Sisi Tunggal/ Pisau Gelombang/ Pisau Gigi/ Pisau Kombinasi |

| Tipe Baja | /S50C/C55 |

| Ketebalan (mm) | 0.45/0.53/2pt/3pt/4pt/6pt |

| Dhuwur (mm) | 7.0/8.0/9.5/12/23.5/23.6/23.7/23.8/30 ~ 100 mm |

| Kekerasan badan (Hrc) | 33/37/41/45/48/ |

| Kekerasan Blade (Hrc) | 54/56/58/60/ |

| Sudut Blade | ∠30° ∠42° ∠52° |

| liyane | Pengerasan perawatan panas frekuensi dhuwur, penggilingan pinggiran pisau, pangolahan pangilon pinggiran pisau. |

Kekandelan toleransi sawetara aturan CUTTING

| kekandelanEkspresi | Referensi | InternasionalStandar | Standar Perusahaan | |

| Toleransi | Min~Maks | |||

| 0.45 | 0.44 | ± 0,025 | ± 0,010 | 0,430~0,450 |

| 2 PT | 0.71 | ± 0,030 | ± 0,010 | 0,700-0,720 |

| 3 PT | 1.05 | ± 0,040 | ± 0,010 | 1.050~1.070 |

| 4 PT | 1.42 | ± 0,050 | ± 0,015 | 1.395~1.425 |

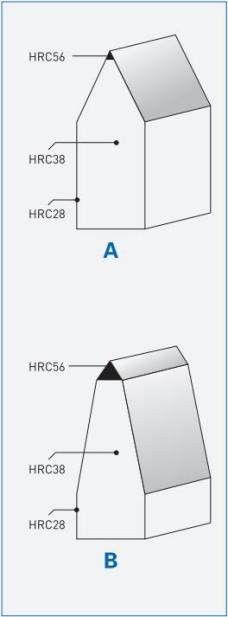

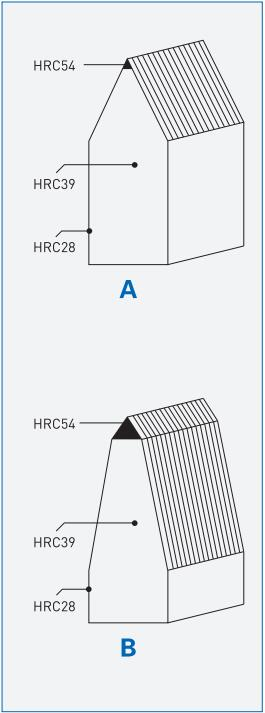

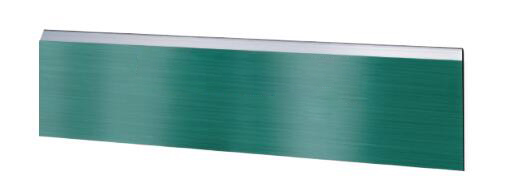

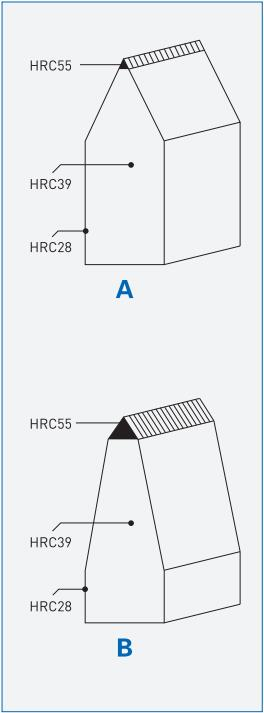

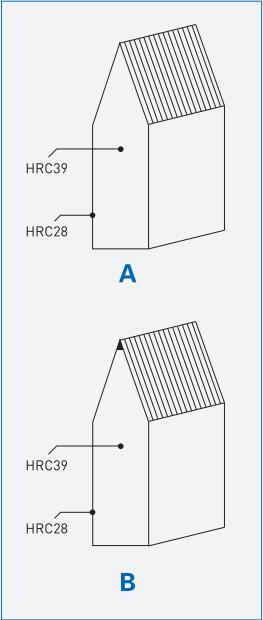

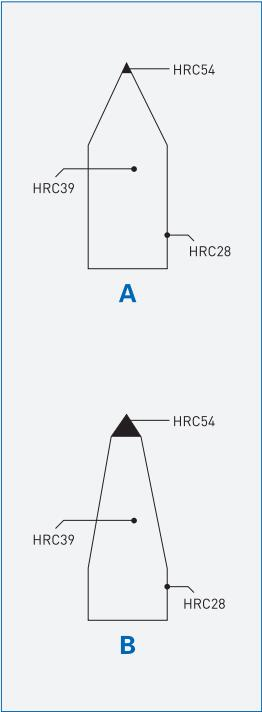

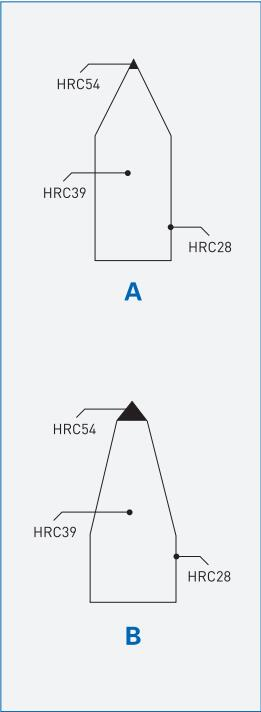

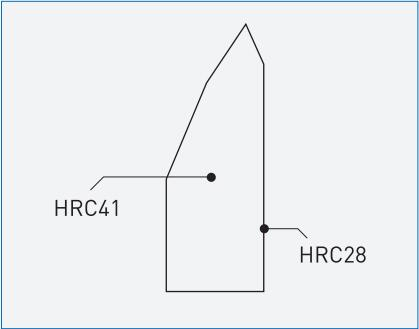

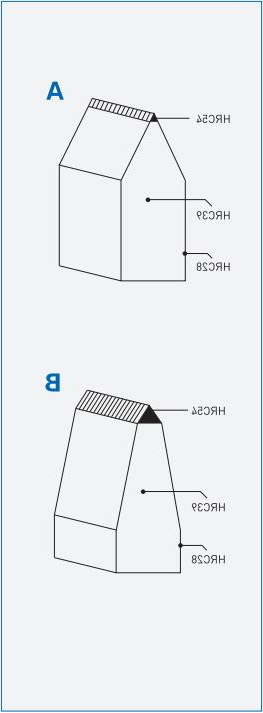

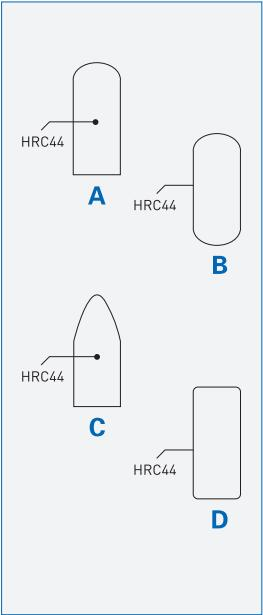

Dampak saka Blade Angle ing Product

Pilihan Blade

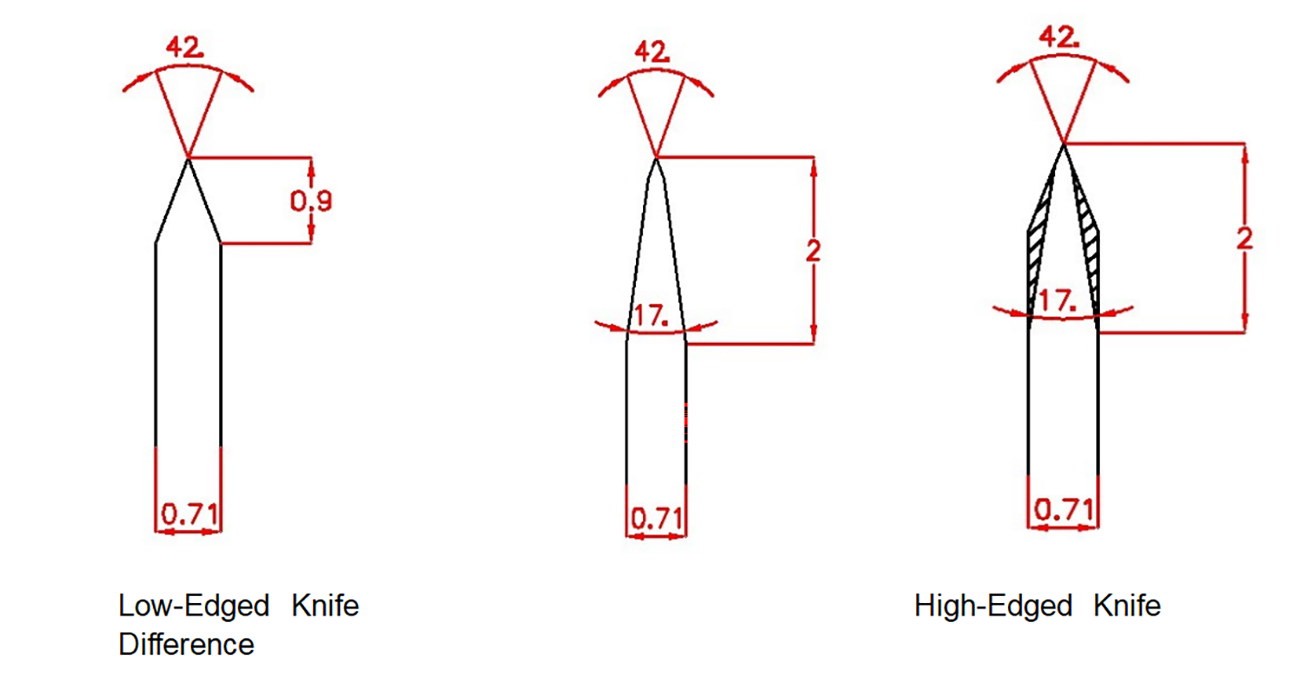

1. Bèntenipun Piso High-edged lan Low-edged

Bentenipun antarane piso dhuwur-edged lan kurang-edged iku piso dhuwur-edged adhedhasar piso kurang edged banjur grinds mati sudhut ing loro-lorone kanggo nggawe agul-agul sawijining sempit, umume bab 2mm.

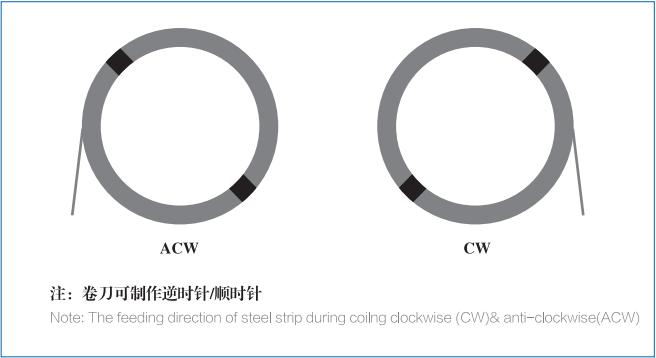

Paket

| kekandelan | Jumlah kothak karton | Koil |

| 0,45 mm (1,27 PT) | 100pcs / kothak | 100M / Coil |

| 0,53 mm (1,5 PT) | 100pcs / kothak | 100M / Coil |

| 0,71 mm (2 PT) | 100pcs / kothak | 100M / Coil |

| 1,07 mm (3 PT) | 70pcs / kothak | 70M/Koil |

| 1,42 mm (4 PT) | 50 pcs/kotak | 50M / Coil |

| 2.10mm(6 PT) | 35 pcs/kotak | 35M / Koil |

Area aplikasi

Die-Cutting kanggo kothak kemasan