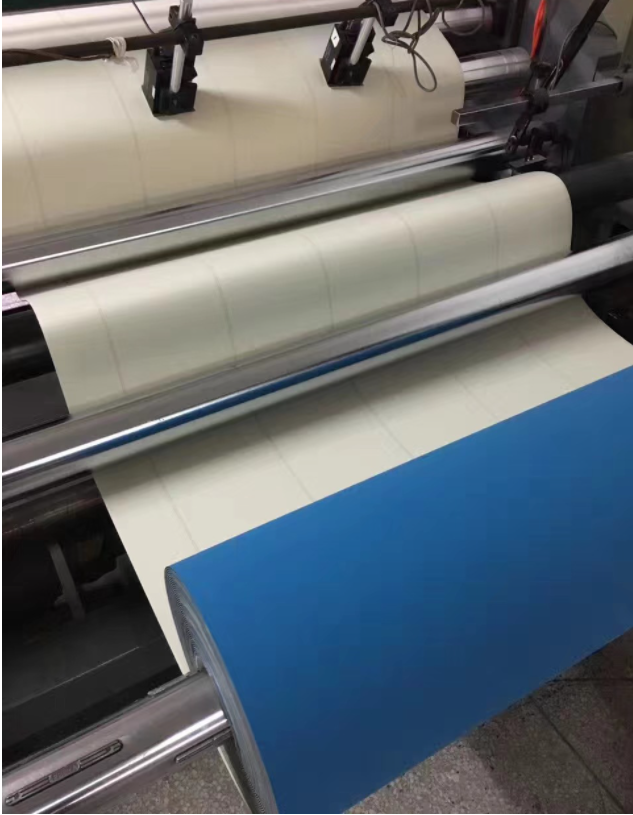

LQ-AB Adhesion Blanket For Offset Printing

Specifications

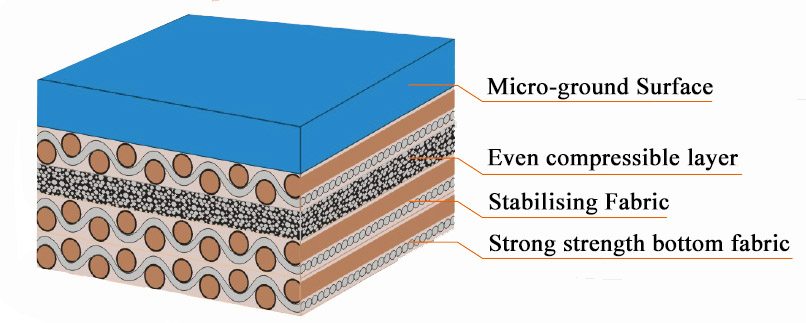

| Construction | Plies fabrics |

| Type | Microsphere |

| Surface | Micro-ground |

| Roughness | 0.90– 1,00 μm |

| Hardness | 78 - 80 shore A |

| Elongation | ≤ 1.2 % at 500 N/5cm |

| Compressibility | 12-18 |

| Colour | Blue |

| Thickness | 1.96mm/1.70mm |

| Thickness tolerance | +/- 0,02mm |

Structure

Blanket On Machine

Precautions during usage

1. As the blanket has the hot spots of light aging and thermal aging, the blanket to be used after purchase shall be wrapped in black paper and stored in a cool place.

2. When cleaning the rubber blanket, the organic solvent with fast volatility should be selected as the detergent, while the kerosene or its local solvent with slow volatility can easily swell the rubber blanket. When washing, the rubber blanket should be cleaned and wiped dry without leaving any residue. On the one hand, the residue is easy to oxidize and dry up, so that the rubber blanket will age in advance. On the other hand, when printing other products at the residue, the ink color is easy to be uneven at the beginning.

3.After a product is printed, if the shutdown time is long, the tensioning device of the blanket can be loosened tomake the blanket relax and get the opportunity of internal stress recovery, so as to actively prevent stress relaxation.

When changing colors in the printing process, the ink roller must be cleaned. After printing for a period of time,paper wool, paper powder, ink and other dirt will accumulate on the blanket,which will reduce the quality of theprinted matter.Therefore, the blanket should be cleaned in time, especially when printing paper with low strength,the accumulation of paper wool and paper powder is more serious, so it should be cleaned more often.

4. If the ink roller group is not cleaned during color change, the purity of the new ink will be affected. Pay specialattention when changing from dark ink to light ink.If the black ink is replaced by yellow ink, if the black ink is notcleaned, the yellow ink will turn black,which will affect the quality of printed matter. Therefore, the ink roller groupmust be cleaned when changing color.

Warehouse and package