Printing Consumables

-

LQ AGFA Graphic Film

Introduction Film parameters: Film category Laser diode red laser polyester film Photosensitive wavelength 650 ± 20 nm Substrate material Anti-static polyester substrate Film base thickness 100μ (0.1mm) Solid Density 4.2-4.5 Resolution 10μ Security light Dark green, suggested equivalent to T20 ND75 Punching machine Suitable for most general fast punching systems Development temperature 32-35℃ Fixing temperature 32-35℃ Punching time 30-40″ -

LQ Double Sided White/Translucent Laser Printed Medical Film

Introduction Performance characteristics *Unique white matt translucent appearance with hazy, soft and elegant effect. * The material is stiff, the surface is white and smooth, and it is easy to carry out various post-processing. *Waterproof and tear-resistant, suitable for various occasions with strict use requirements. * High temperature resistance and no deformation, suitable for various laser printers, the pattern is firm and scratch-resistant, and does not drop powder. *Environ... -

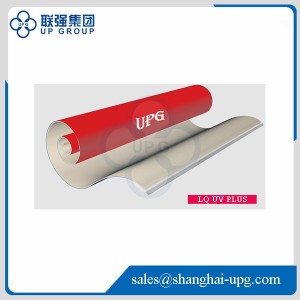

LQ UV Plus Printing Blanket for Offset Printing

LQ UV Plus Type Printing Blanket is developed for sheetfed offset press 12000-15000 sheets per hour. It is appropriate to package and metal UV printing.UV solidification and ultraviolet rays resistant. Convenient use, low thickness reduce for good print quality.

-

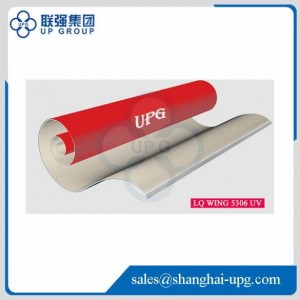

LQ WING 5306 UV Printing Blanket for Offset Printing

LQ Wing 5306 UV Type Printing Blanket is appropriate to package and metal UV printing.UV solidification and ultraviolet rays resistant. Convenient use, low thickness reduce for good print quality. It’s developed for sheetfed offset press 10000 sheets per hour.

-

LQ NS High Speed Printing Blanket for Offset Printing

LQ NS High Speed Type Printing Blanket is developed for sheetfed offset press with 15000 sheets per hour. The dots are clear and round, suitable foe high -quality printing. Prefer to metal print electronic product packaging Mobile phone box packaging.

-

LQ 1090 High Speed Printing Blanket for Offset Printing

LQ 1090 High Speed Type Printing Blanket is developed for sheetfed offset press with 12000-15000 sheets per hour. Good tensile effect, and printing resistance increased by 20%. Wide-ranging print. Prefer to carton print and full mold print.

-

LQ 1050 High Speed Printing Blanket for Offset Printing

LQ 1050 High Speed Type Printing Blanket is developed for sheetfed offset press 10000-12000 sheets per hour. Strong universality, wide-ranging print. Prefer to package print.

-

LQ WING 5000 High Speed Printing Blanket for Offset Printing

LQ WING 5000 High Speed Type Printing Blanket is developed for sheetfed offset press 15000 sheets per hour.Moderate compressibility avoids moving image of machine and reduces the edge marking. Wide-ranging print. Prefer to carton print and full mold print.

-

LQ WING 2000 Economical Type Printing Blanket for Offset Printing

LQ WING 2000 economical type blanket is developed for sheetfed offset press with 9000 sheets per hour. Moderate compressibility avoids moving image of machine and reduces the edge marking. Wide-ranging print. Prefer to carton print and full mold print.

-

LQ-2800 Laser Imagesetter CTF

LQ-2800 High precision, full automatic, 60m lining by roller laser imagesetter without any dark room is the latest product developed by Eastcom in 2004 with full automatictity operation during whole process, grid reverting exactly and high precision resetting and so on. Also it is the ideal choice of large plate making center , news printing, circuit printing and escutcheon trade.

-

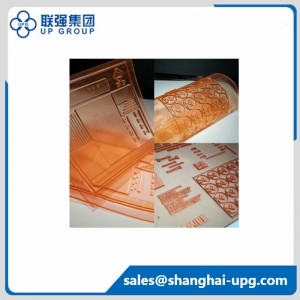

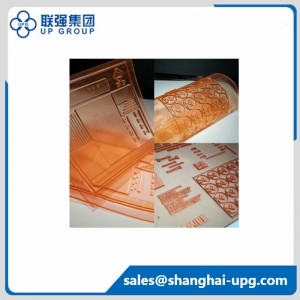

LQ-FP Analog Flexo Plates for Flexible Packaging and Labels

Medium hard plate, optimized for the printing of designs that combine halftones and solids in one plate.Ideal for all absorbent and non-absorbent commonly used substrates (i.e. plastic and aluminium foil, coated and uncoated boards, preprint liner).High solid density and minimum dot gain in the halftone.Wide exposure latitude and good relief depths.Suitable for the use with water and alcohol-based printing inks.

-

LQ-HFS Hot Stamping Foil for paper or plastic stamping

It is made by adding a layer of metal foil on the film base through coating and vacuum evaporation. The thickness of anodized aluminum is generally (12, 16, 18, 20) μ m. 500 ~ 1500mm wide.Hot stamping foil is made by coating release layer, color layer, vacuum aluminum and then coating film on the film, and finally rewinding the finished product.