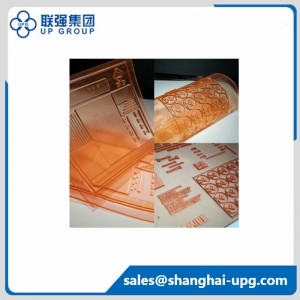

LQ-FP Analog Flexo Plates for Flexible Packaging and Labels

Specifications

| SF-GL | ||

| Analogue Plate for Label & Flexible Packaging | ||

| 170 | 228 | |

| Technical Characteristics | ||

| Thickness (mm/inch) | 1.70/0.067 | 2.28/0.090 |

| Hardness(Shore Å) | 64 | 53 |

| Image Reproduction | 2 – 95% 133lpi | 2 – 95% 133lpi |

| Minimum Isolated Line(mm) | 0.15 | 0.15 |

| Minimum Isolated Dot(mm) | 0.25 | 0.25 |

| Processing Parameters | ||

| Back Exposure(s) | 20-30 | 30-40 |

| Main Exposure(min) | 6-12 | 6-12 |

| Washout Speed(mm/min) | 140-180 | 140-180 |

| Drying Time (h) | 1.5-2 | 1.5-2 |

| Post ExposureUV-A (min) | 5 | 5 |

| Light Finishing UV-C (min) | 5 | 5 |

Note

1.All processing parameters depend on, among others, the processing equipment, lamp age and the type of washout solvent. The above-mentioned values are only to be used as a guide.

2.Suitable for all water based and alcohol-based printing inks. (ethyl acetate content preferably below 15%, ketone content preferably below 5%, not designed for solvent or UV inks) Alcohol based ink can be treated as water ink.

3.All the Flexo plates in the market are all not comparable with solvent ink, they can use but it is their(customers) risk. For UV Ink, so far all of our plates cannot works with UV inks, but some of customer use it and get the good result but it doesn’t mean others one can get the same result. We are now researching the new type of Flexo plates it is works with UV ink.