LQ-DP Digital Plate for Flexible Packaging

For Flexible Packaging and Labels

SF-GL Analog Flexo Plates

• Medium hard plate, optimized for the printing of designs that combine halftones and solids in one plate

• Ideal for all absorbent and non-absorbent commonly used substrates (i.e. plastic and aluminium foil, coated and uncoated boards, preprint liner)

• High solid density and minimum dot gain in the halftone

• Wide exposure latitude and good relief depths

• Suitable for the use with water and alcohol-based printing inks

SF-DGL Digital Flexo Plates

• Superior printing quality with sharper images, more open intermediate depths, finer highlight dots and less dot gain, i.e. larger range of tonal values therefore improved contrast

• Increased productivity and data transfer without loss of quality due to digital workflow

• Consistency in quality when repeating plate processing

• Cost effective and more environmentally friendly in processing, as no film is required

SF-DG Digital Flexo Plates

• A softer digital plate than SF-DGL, which is suitable for label and tags, folding cartons, and sacks, paper, multiwall printing

• Increased productivity and data transfer without loss of quality due to digital workflow

• Consistency in quality when repeating plate processing

• Cost effective and more environmentally friendly in processing, as no film is required

For Corrugated

SF-GT Analog Flexo Plates

• Especially for printing on coarse corrugated fluted board, with uncoated and half coated papers

• Ideal for retail packages with simple designs

• Optimized for use in inline corrugated print production

• Very good ink transfer with excellent area coverage and high solid density

• Perfect adaptation to corrugated board surfaces reduces washboard effect

• Less plate cleaning due to special surface properties

• Extremely robust and durable material thus

▫ high print run stability

▫ excellent storage capability

▫ low swelling characteristic

▫ high resistance to ozone

SF-DGT Digital Flexo Plates

• Superior printing quality with sharper images, more open intermediate depths, finer highlight dots and less dot gain, i.e. larger range of tonal values therefore improved contrast

• Increased productivity and data transfer without loss of quality due to digital workflow

• Consistency in quality when repeating plate processing

• Cost effective and more environmentally friendly in processing, as no film is required

SF-DGS Digital Flexo Plates

• Softer and lower durometer compared to SF-DGT, perfect adaptation to corrugated board surfaces and reduces washboard effect

• Superior printing quality with sharper images, more open intermediate depths, finer highlight dots and less dot gain, i.e. larger range of tonal values therefore improved contrast

• Increased productivity and data transfer without loss of quality due to digital workflow

• Consistency in quality when repeating plate processing

• Cost effective and more environmentally friendly in processing, as no film is required

SF-L Analog Flexo Plates

High plate hardness for reliable print quality

• suitable for a broad range of substrates

• very good and consistent ink transfer with excellent area coverage

• high solid density and minimum dot gain in the halftones

• intermediate depths with excellent contour definition Efficient handling and superior durability

• convenient plate processing with short exposure times, light finishing could be avoided

• high print run stability due to superior resistance against mechanical stress

• long lifetime due to robust and durable material

• reduced cleaning cycles due to special surface properties

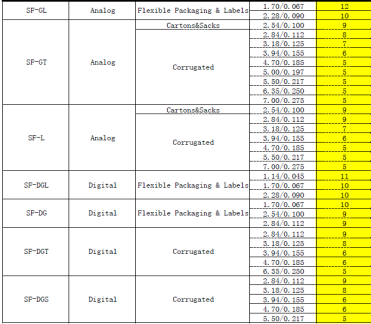

Technical Characteristics and Processing Parameters

| SF-GL | ||

| Analogue Plate for Label & Flexible Packaging | ||

| 170 | 228 | |

| Technical Characteristics | ||

| Thickness (mm/inch) | 1.70/0.067 | 2.28/0.090 |

| Hardness(Shore Å) | 64 | 53 |

| Image Reproduction | 2 – 95% 133lpi | 2 – 95% 133lpi |

| Minimum Isolated Line(mm) | 0.15 | 0.15 |

| Minimum Isolated Dot(mm) | 0.25 | 0.25 |

| Processing Parameters | ||

| Back Exposure(s) | 20-30 | 30-40 |

| Main Exposure(min) | 6- 12 | 6- 12 |

| Washout Speed(mm/min) | 140- 180 | 140- 180 |

| Drying Time (h) | 1.5-2 | 1.5-2 |

| Post ExposureUV-A (min) | 5 | 5 |

| Light Finishing UV-C (min) | 5 | 5 |

| SF-DGL | |||

| Digital Plate for Label & Flexible Packaging | |||

| 114 | 170 | 228 | |

| Technical Characteristics | |||

| Thickness (mm/inch) | 1. 14/0.045 | 1.70/0.067 | 2.28/0.090 |

| Hardness(Shore Å) | 75 | 67 | 55 |

| Image Reproduction | 1 – 98% 175lpi | 1 – 98% 175lpi | 2 – 95% 150lpi |

| Minimum Isolated Line(mm) | 0.10 | 0.10 | 0.10 |

| Minimum Isolated Dot(mm) | 0.15 | 0.15 | 0.20 |

| Processing Parameters | |||

| Back Exposure(s) | 40-60 | 50-70 | 80- 100 |

| Main Exposure(min) | 10- 15 | 10- 15 | 10- 15 |

| Washout Speed(mm/min) | 160- 180 | 140- 180 | 130- 170 |

| Drying Time (h) | 1.5-2 | 1.5-2 | 2-2.5 |

| Post ExposureUV-A (min) | 5 | 5 | 5 |

| Light Finishing UV-C (min) | 4 | 4 | 4 |

| SF-DG | |||

| Digital Plate for Label & Flexible Packaging | |||

| 170 | 254 | 284 | |

| Technical Characteristics | |||

| Thickness (mm/inch) | 1.70/0.067 | 2.54/0.100 | 2.84/0. 112 |

| Hardness(Shore Å) | 62 | 55 | 52 |

| Image Reproduction | 1 – 98% 150lpi | 2 – 95% 150lpi | 2 – 95% 130lpi |

| Minimum Isolated Line(mm) | 0.10 | 0.10 | 0.10 |

| Minimum Isolated Dot(mm) | 0.15 | 0.15 | 0.20 |

| Processing Parameters | |||

| Back Exposure(s) | 50-70 | 80- 100 | 80- 100 |

| Main Exposure(min) | 10- 15 | 10- 15 | 10- 15 |

| Washout Speed(mm/min) | 140- 180 | 130- 170 | 120- 140 |

| Drying Time (h) | 1.5-2 | 2-2.5 | 2-2.5 |

| Post ExposureUV-A (min) | 5 | 5 | 5 |

| Light Finishing UV-C (min) | 4 | 4 | 4 |

| SF-GT | ||||||||

| Analogue Plate for Carton (2.54) & Corrugated | ||||||||

| 254 | 284 | 318 | 394 | 470 | 500 | 550 | 635 | 700 |

| Technical Characteristics | ||||||||

| 2.54/0.100 | 2.84/0.112 | 3.18/0.125 | 3.94/0.155 | 4.70/0.185 | 5.00/0.197 | 5.50/0.217 | 6.35/0.250 | 7.00/0.275 |

| 44 | 41 | 40 | 38 | 37 | 36 | 35 | 35 | 35 |

| Image Reproduction | 2 – 95% 100lpi | 3 – 95% 100lpi | 3 – 95% 80lpi | 3 – 90% 80lpi | 3 – 90% 80lpi | 3 – 90% 80lpi | 3 – 90% 60lpi | 3 – 90% 60lpi | 3 – 90% 60lpi |

| Minimum Isolated Line(mm) | 0.15 | 0.20 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 |

| Minimum Isolated Dot(mm) | 0.25 | 0.30 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| Back Exposure(s) | 30-40 | 40-60 | 60-80 | 80- 100 | 90- 1 10 | 90- 110 | 150-200 | 250-300 | 280-320 |

| Main Exposure(min) | 6- 12 | 8- 15 | 8- 15 | 8- 15 | 8- 18 | 8- 18 | 8- 18 | 8- 18 | 8- 18 |

| Washout Speed(mm/min) | 140- 180 | 140- 160 | 120- 140 | 90- 120 | 70- 100 | 60-90 | 50-90 | 50-90 | 50-90 |

| Drying Time (h) | 1.5-2 | 1.5-2 | 1.5-2 | 2-2.5 | 2-2.5 | 3 | 3 | 3 | 3 |

| Post ExposureUV-A (min) | 5 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Light Finishing UV-C (min) | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| SF-L | |||||||

| Analogue Plate for Carton (2.54) & Corrugated | |||||||

| 254 | 284 | 318 | 394 | 470 | 550 | 700 | |

| Technical Characteristics | |||||||

| Thickness (mm/inch) | 2.54/0.100 | 2.84/0.112 | 3.18/0.125 | 3.94/0.155 | 4.70/0.185 | 5.50/0.217 | 7.00/0.275 |

| Hardness(Shore Å) | 50 | 48 | 47 | 43 | 42 | 40 | 40 |

| Image Reproduction | 3 – 95% 100lpi | 3 – 95% 100lpi | 3 – 95% 100lpi | 3 – 90% 80lpi | 3 – 90% 80lpi | 3 – 90% 60lpi | 3 – 90% 60lpi |

| Minimum Isolated Line(mm) | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 |

| Minimum Isolated Dot(mm) | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| Back Exposure(s) | 30-40 | 35-60 | 50-70 | 60-80 | 90- 1 10 | 150-200 | 280-320 |

| Main Exposure(min) | 8- 15 | 8- 15 | 8- 15 | 8- 15 | 8- 18 | 8- 18 | 8- 18 |

| Washout Speed(mm/min) | 130- 150 | 120- 140 | 100- 130 | 90- 1 10 | 70-90 | 70-90 | 70-90 |

| Drying Time (h) | 1.5-2 | 1.5-2 | 1.5-2 | 2-2.5 | 3 | 3 | 3 |

| Post ExposureUV-A (min) | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Light Finishing UV-C (min) | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 |

| SF-DGT | |||||

| Digital Plate for Corrugated | |||||

| 284 | 318 | 394 | 470 | 635 | |

| Technical Characteristics | |||||

| Thickness (mm/inch) | 2.84/0.112 | 3.18/0.125 | 3.94/0.155 | 4.70/0.185 | 6.35/0.250 |

| Hardness(Shore Å) | 42 | 41 | 37 | 35 | 35 |

| Image Reproduction | 2 – 95% 120lpi | 2 – 95% 120lpi | 2 – 95% 100lpi | 3 – 95% 80lpi | 3 – 95% 80lpi |

| Minimum Isolated Line(mm) | 0.10 | 0.20 | 0.30 | 0.30 | 0.30 |

| Minimum Isolated Dot(mm) | 0.20 | 0.50 | 0.75 | 0.75 | 0.75 |

| Back Exposure(s) | 70-90 | 80- 110 | 90- 120 | 110- 130 | 250-300 |

| Main Exposure(min) | 10- 15 | 10- 15 | 10- 15 | 10- 15 | 10- 15 |

| Washout Speed(mm/min) | 120- 140 | 100- 130 | 100- 130 | 70- 100 | 50-90 |

| Drying Time (h) | 2-2.5 | 2.5-3 | 3 | 3 | 3 |

| Post ExposureUV-A (min) | 5 | 5 | 5 | 5 | 5 |

| Light Finishing UV-C (min) | 4 | 4 | 4 | 4 | 4 |

| SF-DGS | |||||

| Digital Plate for Corrugated | |||||

| 284 | 318 | 394 | 470 | 550 | |

| Technical Characteristics | |||||

| Thickness (mm/inch) | 2.84/0.112 | 3.18/0.125 | 3.94/0.155 | 4.70/0.185 | 5.50/0.217 |

| Hardness(Shore Å) | 35 | 33 | 30 | 28 | 26 |

| Image Reproduction | 3 – 95% 80lpi | 3 – 95% 80lpi | 3 – 95% 80lpi | 3 – 95% 60lpi | 3 – 95% 60lpi |

| Minimum Isolated Line(mm) | 0.10 | 0.25 | 0.30 | 0.30 | 0.30 |

| Minimum Isolated Dot(mm) | 0.20 | 0.50 | 0.75 | 0.75 | 0.75 |

| Back Exposure(s) | 50-70 | 50- 100 | 50- 100 | 70- 120 | 80- 150 |

| Main Exposure(min) | 10- 15 | 10- 15 | 10- 15 | 10- 15 | 10- 15 |

| Washout Speed(mm/min) | 120- 140 | 100- 130 | 90- 1 10 | 70-90 | 70-90 |

| Drying Time (h) | 2-2.5 | 2.5-3 | 3 | 4 | 4 |

| Post ExposureUV-A (min) | 5 | 5 | 5 | 5 | 5 |

| Light Finishing UV-C (min) | 4 | 4 | 4 | 4 | 4 |